Jul 25, 2025

Single row tapered roller bearings use a cone-shaped design with line contact between rollers and raceways, unlike ball bearings that rely on point contact. This unique structure allows these bearings to support high radial loads and axial loads in one direction, making them essential in machinery such as automotive wheel hubs and heavy-duty equipment. Their separable components—cup, cone, and cage—ensure precise alignment and load distribution. Industries like automotive and industrial machinery account for most global demand for single row tapered roller bearings.

Key Takeaways

Single row tapered roller bearings use cone-shaped rollers to handle heavy radial and axial loads efficiently.

Their design with line contact increases load capacity and reduces friction, making them durable and reliable.

These bearings are common in automotive wheel hubs and heavy industrial machinery due to their strength and precision.

Proper lubrication, correct installation, and regular maintenance are essential to extend bearing life and performance.

While they offer high load support, tapered roller bearings need careful alignment and have speed limits compared to ball bearings.

Design of Single Row Tapered Roller Bearings

Components

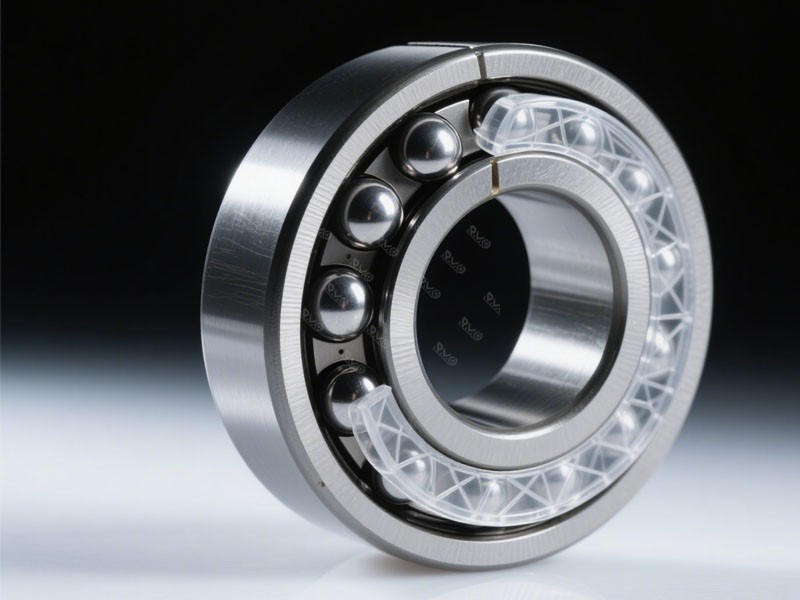

Single row tapered roller bearings have four main components.

Inner ring

Outer ring

Tapered rollers

Cage

The inner ring, also called the cone, fits onto the shaft. The outer ring, or cup, sits in the housing. Tapered rollers fit between these rings and roll along the raceways. The cage keeps the rollers evenly spaced and stable during operation. Each part plays a specific role. The rings and rollers carry the load. The cage prevents the rollers from touching each other, which reduces friction and wear.

Material selection for each component affects the performance of the bearing. Manufacturers often use high-quality steel for the rings and rollers. The cage may use pressed steel or other durable materials. These choices help the bearing last longer and handle heavy loads.

Single row tapered roller bearings come in many sizes. Their bore diameter, outer diameter, and width follow international standards. This standardization ensures that the bearings fit many types of machinery. Tolerances for these bearings follow strict guidelines. These tolerances help reduce vibration and improve the life of the bearing. Designers can choose from different tolerance classes, such as ABEC 1 for normal use or ABEC 5 for higher precision.

Tapered Rollers

Tapered rollers give these tapered rollers bearings their unique ability to handle both radial and axial loads. The rollers and raceways have a conical shape. All the cones' points meet at a single spot on the bearing axis. This design creates a line contact between the rollers and the raceways, not just a point. The result is a larger contact area, which allows the bearing to support heavier loads.

The conical geometry of the rollers ensures proper rolling motion. The rollers move smoothly along the raceways without sliding. This reduces friction and heat. The contact angle, set by the taper, affects how much axial load the bearing can handle. A steeper angle means the bearing can support more thrust.

A flange on the inner ring keeps the rollers in place. This prevents them from slipping out during operation. The precise alignment of the cones also increases the rigidity of the bearing. This rigidity helps keep the shaft in the correct position, even under heavy loads.

Recent advancements in tapered roller bearing design have improved performance. Manufacturers now use induction hardening to make the raceways tougher. Superfinishing the raceway surfaces reduces friction and wear. Some designs use two single-row tapered roller bearings together to handle even greater loads. Engineers use computer models to optimize load distribution and preload. These improvements help the bearings last longer and work better in demanding applications.

Technological Advancement

Description

Induction Hardening Process

Hardens raceways for better durability.

Superfinishing of Raceway Surface

Makes surfaces smoother to reduce friction and wear.

Dual Bearing Arrangement

Uses two single-row bearings together for higher load capacity.

Load Distribution and Preloading

Uses precise calculations to balance loads and reduce vibration.

Application Focus

Designs bearings for specific uses, such as wind turbines, to meet special performance needs.

Lubrication methods also play a key role in bearing performance. Grease and oil reduce friction and heat. Solid lubricants work well in extreme conditions. Self-lubricating materials can help in special environments. Regular maintenance and monitoring of lubrication systems keep the bearings running smoothly and extend their service life.

Single row tapered roller bearings rely on their design to deliver high performance. The convergence of the conical apices at a common point ensures that the rollers move in a true rolling motion. This alignment allows the bearing to handle both radial and axial loads efficiently. The combination of strong materials, precise geometry, and advanced manufacturing makes these bearings a top choice for many industries.

Load Handling in Tapered Roller Bearings

Single row tapered roller bearings stand out because they can support both radial and axial loads at the same time. This unique ability comes from their special design, which uses conical rollers and raceways. The way these bearings handle loads makes them a top choice for many machines that need strength and reliability.

Radial Loads

Radial loads act perpendicular to the shaft. Tapered roller bearings manage these forces with ease. The rollers sit between the inner and outer rings, spreading the force along a line of contact. This design increases the contact area, which helps the bearing carry heavier loads without wearing out quickly.

The maximum radial load capacity for a standard single row tapered roller bearing depends on several factors. Engineers use the basic dynamic load rating, called Cr, to measure how much force the bearing can handle while moving. The actual load applied is Fr, and under pure radial load, the equivalent dynamic bearing load (P) equals Fr. When both radial and axial loads are present, P is calculated using special factors (e and Y) that depend on the ratio of axial to radial load. The table below summarizes these key parameters:

Parameter

Description

Cr

Basic dynamic load rating (N), shows maximum dynamic radial load capacity

Fr

Radial load (N), actual force on the bearing

Fa

Axial load (N), force along the shaft

P

Equivalent dynamic bearing load (N), used for life estimation; P = Fr for pure radial load

e, Y

Factors for combined loads, based on Fa/Fr ratio

L

Bearing life, calculated as L = (Cr / P)^p

C0r

Basic static load rating (N), used for safety and minimum load needs

A single row tapered roller bearing needs a minimum radial load greater than C0r/60 to prevent slippage. This rule helps keep the rollers moving smoothly and avoids damage. The contact angle also plays a big role. A larger contact angle increases the bearing's ability to handle radial loads and makes it stiffer. This means the bearing can support more weight and last longer in tough jobs.

Axial Loads

Axial loads push or pull along the shaft. Tapered roller bearings handle these forces better than many other types of bearings. The secret lies in the contact angle. This angle, which ranges from 10° to 29°, changes how the bearing manages force. A larger contact angle lets the bearing support more axial load. This makes tapered roller bearings perfect for jobs where both radial and axial forces are present.

Compared to ball bearings, a single row tapered roller bearing can hold up to 20% more axial load for the same size. Cylindrical roller bearings, on the other hand, mainly support radial loads and have limited ability to handle axial forces.

In many machines, a single row tapered roller bearing supports axial loads in only one direction. To handle forces from both directions, engineers often use two bearings in pairs. This paired arrangement allows the bearings to balance axial forces, provide better guidance, and extend the life of the equipment. Paired bearings also make maintenance easier, since each bearing can be adjusted or replaced separately.

Paired single row tapered roller bearings:

Support axial loads in both directions

Distribute combined loads evenly

Reduce wear and extend service life

Offer design flexibility for different machines

The contact angle not only affects load capacity but also changes the stiffness of the bearing. A larger angle increases both radial and axial stiffness, making the bearing more stable during operation. This stability is important in high-speed or heavy-duty applications, such as automotive wheel hubs and construction machinery.

Tapered roller bearings combine smart design with strong materials to handle tough jobs. Their ability to support both radial and axial loads, especially when used in pairs, makes them a reliable choice for many industries.

Comparison with Other Bearings

Ball Bearings

Ball bearings and tapered roller bearings serve different roles in machinery. Ball bearings use point contact between the balls and raceways. Tapered roller bearings use line contact, which creates a larger contact area. This difference affects how each bearing handles loads and where engineers use them.

Aspect

Single Row Tapered Roller Bearings

Ball Bearings

Contact Type

Line contact (larger contact area)

Point contact (smaller contact area)

Load Handling

High radial and axial load capacity, suitable for combined loads

Lower load capacity, mainly radial loads

Typical Applications

Vehicle hubs, heavy-duty machinery

Electric motors, gearboxes, precision instruments

Speed Capability

Moderate speeds, higher friction

High speeds, lower friction

Sensitivity to Misalignment

More sensitive, less forgiving

More tolerant to slight misalignment

Deformation Under Load

More deformation, less precision

Less deformation, better for precision applications

Tapered roller bearings handle both radial and axial loads at the same time. Ball bearings mainly support radial loads and work best at high speeds. Tapered roller bearings perform well in heavy-duty jobs, such as construction and mining equipment. Ball bearings fit better in electric motors and devices that need high speed and precision. Tapered roller bearings show more deformation under heavy loads, while ball bearings keep their shape better, which helps in precision tasks.

Cylindrical Roller Bearings

Cylindrical roller bearings and tapered roller bearings both use rollers instead of balls. However, their designs and uses differ. Cylindrical roller bearings mainly support radial loads. Tapered roller bearings support both radial and axial loads because of their conical shape.

Cylindrical roller bearings have low tolerance for misalignment. Even a small angle can cause extra stress and wear. Tapered roller bearings offer slightly better misalignment tolerance than cylindrical roller bearings, but both types need careful alignment during installation. Spherical roller bearings, not covered here, handle misalignment much better.

Tapered roller bearings stand out for their combined load capability. Their tapered geometry allows them to transmit both radial and axial forces efficiently. This makes them ideal for vehicle hubs, gearboxes, and heavy machinery. The design also lets users adjust the bearing clearance during installation, which helps achieve precise performance. Cylindrical roller bearings, in contrast, work best in applications with only radial loads, such as electric motors and pumps.

Key points about tapered roller bearings:

Handle both radial and axial loads

Distribute loads evenly with line contact

Allow adjustment of bearing clearance

Require precise alignment for best results

Tapered roller bearings provide versatility and strength in many demanding applications. Their ability to manage combined loads and their precise adjustment options make them a top choice for engineers.

Applications of Single-Row Tapered Roller Bearing

Single-row tapered roller bearing designs play a vital role in many industries. Their ability to handle both radial and axial loads makes them a top choice for demanding applications. The most common uses appear in the automotive sector and industrial machinery.

Automotive

Automotive engineers rely on single-row tapered roller bearings for several critical functions. These bearings appear in:

Wheel bearings for front and rear wheels

Gearboxes and differentials

Pinion configurations

Wheel bearings must support the vehicle’s weight and forces from turning or braking. The single-row design handles these combined loads efficiently. Bearings in gearboxes and differentials also face high stress and need to maintain precise alignment. Automotive bearings must offer high load capacity, long service life, and smooth operation. They need to resist contaminants and work well under changing conditions. Proper lubrication and careful mounting help ensure reliable performance. Size and fit matter, so engineers select bearings with the right bore diameter, outer diameter, and width.

Industrial Machinery

Single-row tapered roller bearings also serve in heavy-duty industrial equipment. Common applications include:

Conveyors and crushers

Presses and rotary systems

Gear drives

These machines require bearings that can handle heavy radial and axial loads. The single-row design provides effective load distribution and low friction. Bearings often work in pairs with preload to increase rigidity and stability. The separable rings make mounting and maintenance easier. Key factors for selection include load capacity, speed, rigidity, and resistance to harsh environments. Lubrication and protective coatings help bearings last longer in tough conditions.

For reliable performance, many companies choose products from Guangzhou Rimao Bearing Co., Ltd. These brands offer quality and durability for both automotive and industrial needs.

Arrangement Options for Bearings

Engineers use different arrangements to meet specific load requirements. The table below shows common options:

Arrangement

Description

Load Distribution Effect

Tandem

Bearings face the same direction

Share loads in one direction, ideal for centrifugal force

Double-cup

Apexes face inward within a double-grooved raceway

Support axial loads from both directions, balanced axial load capacity

Double-cone

Rollers side-by-side, apexes facing outward

High rigidity, handles combined radial and axial loads

Spacer-assembled

Two bearings separated by spacers, orientation varies

Flexible design, load distribution depends on arrangement

Engineers select the best arrangement based on the machine’s needs. This flexibility helps single-row tapered roller bearings perform well in many settings.

Pros and Cons of Tapered Roller Bearing

Advantages

Tapered roller bearings offer several important benefits for mechanical systems. Their design supports both radial and axial forces, making them suitable for many demanding applications. Here are some key advantages:

Superior load capacity comes from the larger contact area between rollers and raceways. This feature allows the bearing to handle heavier loads and distribute force more evenly.

The compact design saves space in machinery, which helps engineers fit bearings into tight spaces.

Precision operation ensures true rolling motion. This reduces wear and extends the service life of the bearing.

Adjustable clearance lets users fine-tune performance and makes maintenance easier.

Tapered roller bearings can support pure radial, pure axial, or combined loads without modification.

Their geometry ensures proper rolling motion with minimal sliding, which reduces friction and heat.

These bearings have a high load capacity, often outperforming other types like spherical or needle roller bearings.

The robust construction and precise manufacturing improve durability and reliability, even in harsh environments.

A comparison with other bearing types shows that single row tapered roller bearings provide reliable and long service life under combined loads. Their optimized roller end design and surface finish help form a lubricant film, reducing friction and wear. This leads to stable operation and longer bearing life, especially in automotive and industrial machinery.

Limitations

Despite their many strengths, tapered roller bearings have some limitations that users should consider.

These bearings are highly sensitive to misalignment. Even a small error during installation can cause extra stress and reduce bearing life.

They have speed limitations compared to ball bearings. High speeds can generate more heat and increase the risk of failure.

Proper installation with the correct preload is critical. Too much preload can cause high temperatures and shorten the service life of the bearing.

Maintenance needs can impact the total cost of ownership. Routine servicing, lubrication, and downtime for repairs may increase expenses over time.

Limitation

Impact on Performance

Sensitivity to misalignment

Can lead to premature wear or failure if not installed correctly

Speed limitations

Not suitable for very high-speed applications

Maintenance requirements

Increases total cost of ownership due to servicing and downtime

Advanced bearing designs can help reduce maintenance needs and lower costs. For example, split-to-shaft housed units and improved lubrication systems can extend bearing life and reduce downtime. However, these solutions may come with higher upfront costs.

Single row tapered roller bearings support both radial and axial loads, making them essential in automotive, industrial, and heavy machinery. When selecting these bearings, engineers should consider factors such as roller material, bearing design, seals, cage type, ABEC grade, and lubricant.

Regular lubrication, proper installation, and routine inspection help prevent common failures like misalignment or contamination.

Guangzhou Rimao Bearing Co., Ltd. provide products with certifications such as CE, RoHS, ensuring quality and reliability. Welcome to consult: admin@rmbearing.com

Read More